Core Technology Showcase

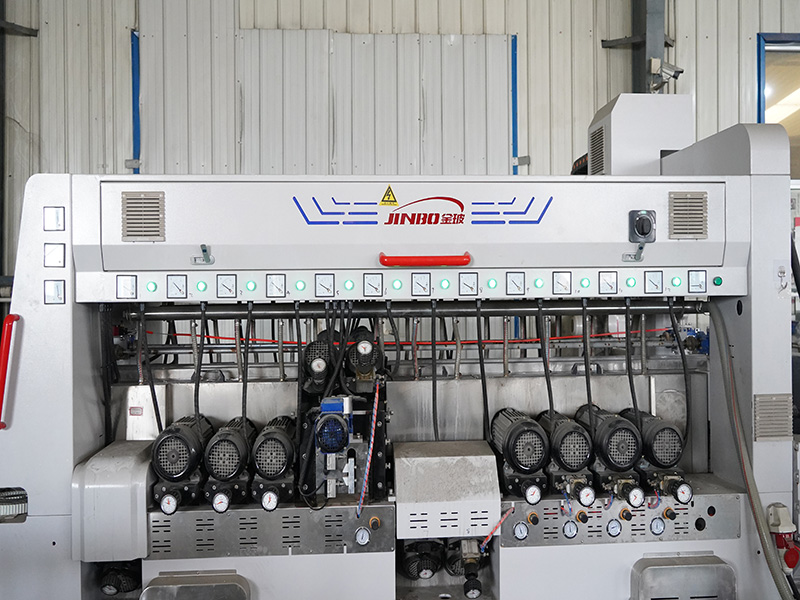

Automated Production Line

Detailed technical parameters and advantages of our automated production line. For example, our line is equipped with the latest XYZ brand robotic arms, capable of 24-hour uninterrupted operation, increasing production efficiency by 50%. We are committed to enhancing precision and reducing manual errors through automation, ensuring every product meets the highest quality standards.

Key Features:

- 50% Increase in Production Efficiency

- 24/7 Uninterrupted Operation

- High Precision & Consistency

- Reduced Manual Errors

Precision Laser Cutting

Discover our advanced laser cutting capabilities, including equipment models, cutting accuracy, and applicable materials. We utilize state-of-the-art fiber laser cutting machines for high-precision, high-speed cutting on various materials, resulting in smooth edges that require no secondary processing. This technology allows us to handle complex designs and ensure perfect component fitting.

Applicable Materials:

- Metal Sheets (Stainless Steel, Carbon Steel, Aluminum Alloy)

- Acrylic and Various Plastic Sheets

- Wood and Composite Boards

- Cutting Accuracy up to ±0.05mm

Intelligent Quality Inspection

Learn about the working principles, detection range, and accuracy of our AI visual inspection system. By integrating high-definition cameras and intelligent image analysis algorithms, our AI quality inspection system automatically identifies minute surface defects, dimensional deviations, and color discrepancies, ensuring every product leaving our factory meets a zero-defect standard.

Inspection Capabilities:

- Surface Scratch & Defect Detection

- Dimensional & Shape Deviation Analysis

- Color Consistency Verification

- Detection Accuracy up to 99.9%